Advanced Production Techniques: In-Mold Decorations Explained

Advanced Production Techniques: In-Mold Decorations Explained

Blog Article

Grasping In-Mold Decorations: Techniques, Trends, and Finest Practices for Optimum Results

In the world of production, the art of in-mold decorations stands as a critical facet of product style and manufacturing. In-Mold Decorations. By delving into the methods, trends, and finest practices that underpin successful in-mold decoration procedures, services can open a world of opportunities that not just boost the visual appeal of their products however additionally streamline manufacturing effectiveness and bolster consumer engagement.

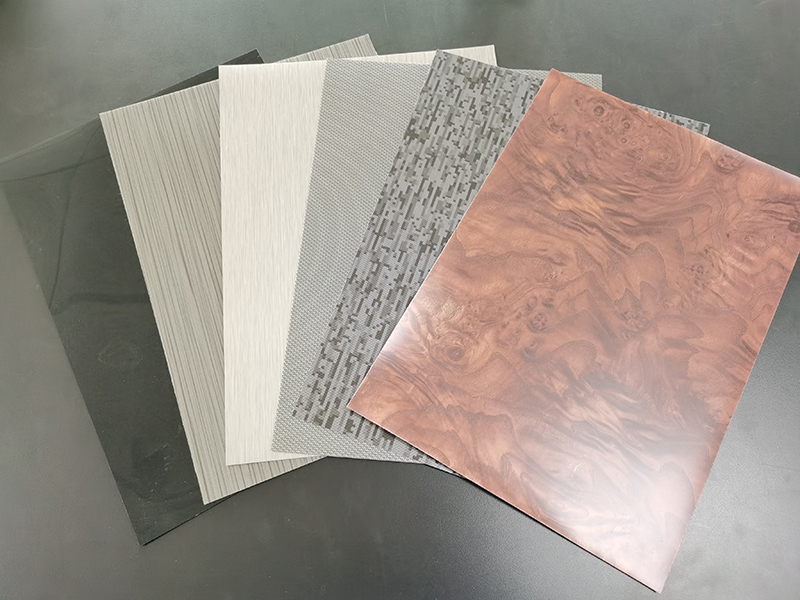

Product Selection

Product selection is a critical aspect of understanding in-mold designs, as it directly impacts the quality and durability of the last product. When selecting products for in-mold decorations, it is vital to take into consideration factors such as compatibility with the molding process, the preferred visual outcome, and the ecological conditions the item will certainly encounter.

In addition, the picked material must have great adhesion properties to make certain that the decoration sticks securely to the substrate during the molding process. Attachment between the design and the product is critical for stopping delamination and making certain long-lasting visual appeal. Additionally, products with high warm resistance are favored for in-mold decorations, specifically for products that will be subjected to elevated temperatures during their lifecycle. By carefully picking the suitable product for in-mold decors, makers can improve the overall high quality and resilience of their items, fulfilling the assumptions of both end-users and clients.

Design Technology

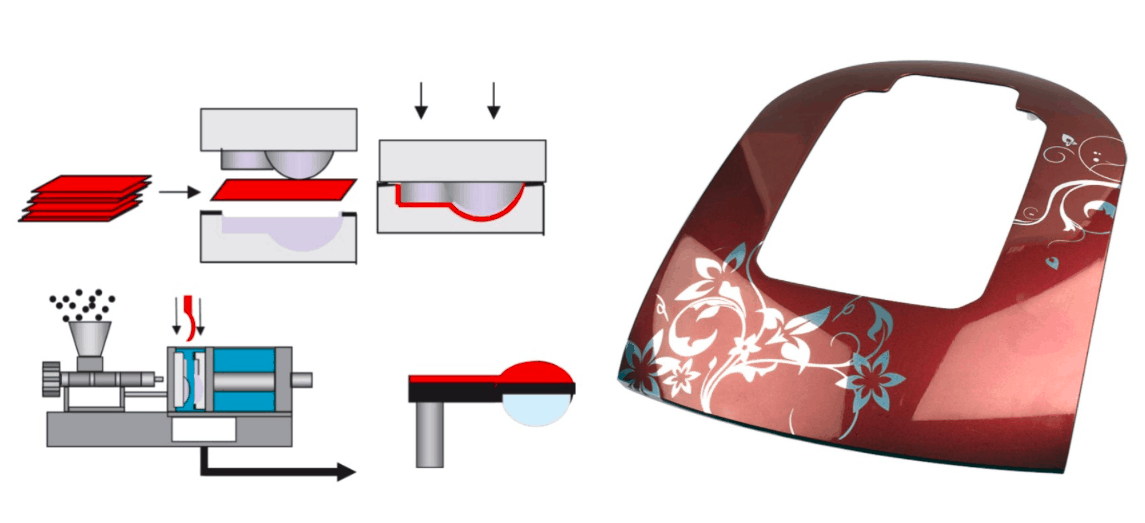

An important consider advancing the field of in-mold decorations is the continuous expedition and implementation of layout innovation strategies. Layout advancement plays an important role in boosting the aesthetic appeal, capability, and total quality of products produced making use of in-mold design procedures. By including cutting-edge style components, manufacturers can distinguish their products in the marketplace, draw in consumers, and remain ahead of rivals.

Among the vital aspects of layout development in in-mold decorations is the combination of detailed patterns, appearances, and graphics that were previously challenging to achieve with standard design methods. Advanced technologies such as 3D printing and digital style tools allow designers to create complex and thorough designs that can be flawlessly moved onto molded parts. In addition, the usage of dynamic colors, metal finishes, and unique effects like gloss or matte textures can additionally elevate the aesthetic charm of in-mold enhanced items.

Furthermore, layout innovation prolongs past aesthetic appeals to encompass useful enhancements such as ergonomic forms, integrated features, and personalized components that accommodate certain individual needs. By accepting style innovation, manufacturers can unlock brand-new opportunities for creative thinking, personalization, and item distinction in the competitive landscape of in-mold designs.

Manufacturing Efficiency

Reliable manufacturing processes are necessary for equating the cutting-edge designs developed in the field of in-mold designs right into top quality ended up items that meet market demands and customer expectations. In the realm of in-mold decors, manufacturing efficiency encompasses numerous key elements that add to the general success of the manufacturing process. One critical component is the optimization of mold design and tooling to make sure exact and smooth design transfer onto the last item. By fine-tuning mold setups and purchasing high-grade tooling products, manufacturers can improve performance and consistency in manufacturing.

Additionally, implementing automation and robotics in the production line can significantly boost performance by streamlining repeated tasks and lowering the margin of error. Automation not just speeds up the production process but also enhances accuracy and repeatability, resulting in an extra consistent and high-grade output. Embracing lean production principles, such as just-in-time inventory monitoring and waste reduction approaches, can better enhance production performance by lessening downtime and optimizing source usage. Generally, a holistic approach to manufacturing effectiveness is critical in making the most of the potential of in-mold design methods and accomplishing optimum lead to the affordable market landscape.

Quality Assurance Steps

What are the crucial techniques for making certain stringent quality assurance actions in the realm of in-mold decors? Quality assurance measures are critical in in-mold decoration procedures to make sure the manufacturing of flawless and top notch finished products. One important approach is the i was reading this execution of strenuous assessment methods at every phase of the manufacturing process. This includes carrying out comprehensive visual examinations, dimensional checks, and shade consistency evaluations to recognize any incongruities or flaws at an early stage.

Making use of advanced technologies such as automatic assessment systems can likewise enhance the quality assurance process by providing trustworthy and accurate information for evaluation. These systems can find imperfections that may be missed by hand-operated inspections, thus boosting general item high quality and consistency.

Regular training and advancement programs for workers involved in the in-mold design process can additionally add to keeping top notch criteria. By educating staff on ideal techniques, high quality expectations, and the significance of focus to information, business can cultivate a culture of top quality awareness throughout the company.

Customer Appeal

To improve the marketability of in-mold design items, providing and understanding to consumer preferences play an essential role in identifying their appeal and success. Providing personalization alternatives such as tailored designs, shade variations, and textural elements can dramatically enhance the appeal of in-mold decoration products.

Final Thought

In-mold designs supply a efficient and versatile way to boost item visual appeals. Mastering in-mold decors calls for an alternative method that takes into consideration all facets of the manufacturing process to guarantee success.

In the world of manufacturing, the art of in-mold designs stands as a crucial aspect of product style and production. Style development plays a critical role in boosting the visual allure, functionality, and total article source quality of products produced using in-mold design processes.One of the essential elements of style technology in in-mold designs is the assimilation of intricate patterns, textures, and graphics that were formerly challenging to attain with standard decor methods.Effective production processes are crucial for equating the ingenious layouts created in the field of in-mold designs right into top quality completed products that satisfy market needs and consumer assumptions. Using personalization options such as personalized layouts, shade variations, and textural look at here now elements can substantially boost the charm of in-mold decor items.

Report this page